Just a Little 3D Printer Love in the Workshop

So, picture this: it’s a crisp Saturday morning, the kind that makes you think twice before crawling out of the warm blanket cocoon. There’s a whiff of freshly brewed coffee mingling with the faint odor of sawdust in the air. Honestly, there’s no better smell on Earth if you ask me. The tools are laid out; my trusty old table saw is gathering dust next to my beloved bandsaw, each has its own little history. But there was something new in the mix this time—a 3D printer. Yeah, I still chuckle at the thought of having one of those things in my workshop.

I wasn’t too sure about it at first. It felt like a leap into the unknown, you know? I stumble across this idea when my buddy Rob over at the hardware store mentioned how he printed some jigs and templates. Initially, I kind of laughed it off, thinking, “What are you trying to pull, Rob? A 3D printer in a woodworking shop?”

But then, after a couple of weeks of pondering while scratching my beard, I thought, “Why not? I mean, anything that can speed things up or make my projects easier is worth a shot.” So I scraped together some cash from my DIY job this summer and found a decent printer—an Anycubic i3 Mega, it was called. I still remember unpacking it and inspecting all those shiny parts like a kid on Christmas morning.

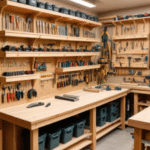

So there I was, a grown man getting giddy over a box of plastic bits. You know how it goes, right? I got it all set up in my workshop, right next to my workbench where the sunlight would catch the filament in a way that honestly felt magical. I loaded up some PLA filament—just the basic stuff, bright green, because I’m no fool; if I’m going plastic, might as well have some fun with it.

The First Project: An Embarrassment

I decided to begin with something simple. A jig. Everybody and their grandma recommends jigs for making precise cuts, so I thought, "Okay, let’s try to make my own." I found this design online—just a clip for holding down smaller wood pieces while cutting. I printed it out while sipping my coffee, all confident-like. The machine whirred and clicked, and I felt like a mad scientist, chucking in ideas and praying they’d come out okay.

So, the first few hours went by, and then, bam! The 3D printer spat out this… well, I don’t know if “crap” is too harsh, but it sure didn’t look like the neat little jig I had pictured in my head. It was more like a squished green blob that vaguely resembled what I wanted. I almost gave up right then and there. I mean, I felt defeated by a little machine. Was I really cut out for this techy stuff?

After moping around with my third cup of coffee, I finally decided to dive into figuring out what went wrong. Turns out, the printer needed some calibrating—who knew? A little tweaking of the bed leveling and adjusting the temperature settings, and I was back in business.

A Small Victory!

When I finally got that jig printed out correctly, I laughed so loud I think the neighbors could hear me. I remember holding it up, looking at my handiwork, and just feeling this rush of pride. I had this little piece of green plastic—nothing fancy—but it was a testament that I’d actually managed to wrestle with technology and come out unscathed.

The real kicker? That jig worked wonders! I used it while cutting some oak for a simple bookshelf I wanted to build for the living room. The sound of that saw sawing through the wood, oh man, it was as if music was playing. And trust me, there’s something about the smell of fresh oak shavings that hits different.

After a few more projects using printouts for knobs and even some decorative inlays, I was hooked. I mean, who wouldn’t be? I started to see the potential of mixing traditional woodworking with this new-age tech. No doubt, there were also some crashes and rough patches when the printer would jam, but that’s part of the journey, right?

Lessons Learned Along the Way

Now, let’s not sit here and pretend it was all smooth sailing. I had my share of mistakes. There was this one time when I underestimated how small a detail could get, and I fired up the ol’ printer for an intricate piece. The print failed, I think, within 15 minutes, splattering green plastic all over the bed. It looked like a sick cartoon frog exploded.

But it was all part of the ride. Each failure taught me something: how to properly scale designs, how to clean the nozzles, and most importantly, how to be patient. Ya know, the smell of burnt plastic can make you feel like you’re losing your sanity, but each failure also brought about a bit more knowledge, a bit more confidence.

Wrap-Up: Just Go for It

So, here I am now, a small-town woodworker who decided to embrace the smell of a little melted plastic alongside the sweet smell of sawdust. Deer hunting in the woods has its charm, but there’s a strange satisfaction in knowing that you can blend the old with the new. If you’re out there thinking about getting a 3D printer for your workshop, just go for it. Sure, you may end up with a witch’s brew of odd shapes and random failures—but trust me, somewhere in there, there’s a nugget of gold waiting for you.

Life’s too short for cluttered workspaces and half-finished projects. Just dip your toes in, mess around, and before long, you’ll be sprouting ideas faster than kids in a candy store. And isn’t that what it’s all about? Enjoying the process and laughing a little along the way?