The Whirring Wonders of Automation in Woodworking

You know, it’s funny how life can twist and turn. One minute, you’re just an average dude from a small town, barely keeping up with the daily grind, and the next, you’re knee-deep in sawdust, trying out things that sound like they belong in some high-tech factory instead of your garage. Yeah, I’m talking about automated woodworking production lines, and boy, have I got a story for you.

A Little Backstory

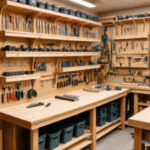

For years, I’ve been the go-to guy for custom furniture in our neighborhood. Nothing too fancy, just solid pieces made from good ol’ oak and pine. My workshop, well, more like a glorified shed, had all the basics: a table saw, a planer from the ’90s that sounds like a grumpy old man, and a dusty router. But as my side gig really started to pick up, especially during the pandemic when folks needed new desks, I realized I was drowning. I needed a way to speed things up, and that’s where I stumbled into the world of automation.

It sounded great—machine-assisted everything! I mean, imagine a production line rolling out perfectly cut pieces while I sip my coffee. But, you know, when you dive into something new, there’s a learning curve, and I hit mine head-on.

The First Mistake

I remember the day I finally decided to buy a CNC router. I had read some reviews about a brand called Shapeoko, and it seemed to be a good fit for a rookie like myself. I pictured that beauty delivering clean, precise cuts while I blasted my favorite classic rock playlist. I even set up a little corner in my shed, free of clutter, just for this machine. Way more thought than I’d given to my own home office before.

But here’s where it spiraled a bit. I set it up, proper-like, feeling like a king. I even filmed the initial test run. But when I hit ‘start,’ instead of that satisfying hum I craved, I got a loud screeching noise. The machine jerked and stopped. I laughed nervously, looking around as if the wood itself might have had some sympathy and said, “Hey, it’s okay, buddy.” Spoiler alert: It didn’t.

Turns out I had forgotten to calibrate the darn thing. I almost gave up when I saw all those wires and settings—like some electrical sorcery I’d never even thought I’d need to know. I contemplated going back to my trusty table saw, but I took a deep breath (or five) and dove into online forums. I’m telling you, YouTube is a goldmine. After a few late-night rabbit holes, I got it figured out.

The Smell of Success

Eventually, I managed to hone in on the correct settings. The day I ran that first successful batch of walnut drawer fronts—man, that smell! Freshly cut walnut has this rich, earthy aroma, and I couldn’t get enough of it. I let it linger in my little space for hours. The sound of the router slicing clean lines was music to my ears, and I had to resist the urge to dance around like a fool. I mean, who knew a hunk of wood could make a guy feel that victorious?

But it wasn’t all smooth sailing from there. I was obsessed with pushing the limits. I thought I’d try to run multiple pieces simultaneously—“Let’s make this a production line,” I thought. What I ended up with was a jammed machine and a massive lump of mahogany I had to wrestle out like a stubborn toddler trying to fit into a too-small jacket. It wasn’t pretty. I laughed when I realized I had a serious wood jam on my hands, but honestly, it was frustrating.

That moment of, “What have you done, you reckless woodworker?” kind of slapped me in the face. Even with all the automation in the world, you can’t rush good craftsmanship. There’s a balance to find, and boy, was I in way over my head trying to crank out 20 furniture pieces in a day.

The Rhythm of Life

After a lot of trial and error, I found a rhythm. Automating certain tasks, like cutting and engraving, gave me so much room to let my creativity shine. I started designing more intricate things—like custom signs and fun decorations for local businesses. It felt good to marry old-school craftsmanship with modern technology.

And I’ll be honest: there’s something humbling about balancing tech with hands-on work. I had to remind myself not to be too quick to dismiss the feel of a well-worn chisel or the patience it takes to sand a corner just right. I realized, in this fast-paced production line world, the heart of woodworking still pulses with that slow, careful touch.

The Takeaway

So, if you’re in a place where you’re considering diving into automated woodworking, just go for it. I wish someone had told me that sooner. It’s gonna be messy, and you might end up with a few scrapes and bruises—figuratively speaking and sometimes literally. But the satisfaction of creating something beautiful, whether it takes two hours or two days, is worth every moment of lost sleep.

In the end, wood has a way of teaching you patience, and every project, automated or not, gives you something back—like the smell of fresh-cut grain or the simple joy of crafting something with your own two hands. So grab that coffee, take a deep breath, and get to it. You never know where it might lead you.