My Journey with a 5-Axis CNC Machine in Woodworking

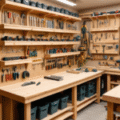

So, let me pour you a cup of coffee and get comfy, because I’ve got a tale to share that’s been brewing in my mind for a while. You see, I stumbled into the world of 5-axis CNC woodworking kind of by accident. One day, I was just your average Joe, tinkering in my little garage workshop, inhaling the sweet scent of freshly cut pine and cedar, dreaming of crafting something that’d make my wife go, “Wow!” instead of the usual nod of approval she gives me when I whip up another plain old shelf.

The First Big Buy

It all started when I really wanted to up my woodworking game. After much deliberation, and maybe a little too much scrolling on the internet, I decided to pull the trigger on a 5-axis CNC machine. Not just any machine, mind you, but a nice mid-range model from a lovely company called Stepcraft. Now, I don’t want to sound like I’m throwing brand names like confetti, but I did my homework, and they had some decent reviews. And you know, it’s a hefty investment, so I was sweating bullets over that decision.

When it arrived, oh boy, was it a sight! It looked like something out of a sci-fi movie. I was excited, but also a bit intimidated. Just setting it up felt like trying to assemble IKEA furniture without the manual—everything looked familiar but somehow at the same time, nothing made sense.

A Lesson in Patience

I remember trying my first project—just a simple sign to hang over our front door, “Welcome to Our Happy Place.” Sounds easy, right? I had this beautiful piece of walnut that I was itching to carve into. I could almost hear the smooth whir of the machine, the satisfying crunch of bits cutting through wood… But then, the nightmare hit. I had the software all set, the design ready to go, but when I hit “Start,” instead of the gentle hum I was expecting, I got this awful grinding noise. Yikes! I didn’t know if I was more scared or just plain confused.

Turns out, I hadn’t calibrated the machine properly. Who knew that these fancy machines needed more babysitting than a toddler? I almost tossed in the towel, convinced I’d made a horrible mistake investing in this beast. I sat there, head in my hands, thinking about how I was going to explain to my wife that I bought a gizmo that could only grind wood into dust.

The Breakthrough Moment

But, you know, something in me said to give it another shot. I pulled up YouTube, watched a couple of tutorials (by the way, thank you, internet!), and slowly pieced together the mystery of machine calibration. Taking a deep breath, I recalibrated that bad boy. I almost laughed at myself when it actually worked—smooth moves, like a well-trained dancer gliding on a wooden stage. I think I may have even done a little victory dance. That moment of relief was euphoric.

So, I set it up again and hit “Start.” And this time, the machine hummed like a dream. The walnut shavings were flying, and the smell of fresh wood filled the garage, making everything feel alive. I could actually see the outline of my design appearing like magic. If only I could bottle that feeling; it was something else.

The Not-So-Perfect Finish

But let me tell you, it wasn’t all sunshine and roses. When I finally sanded down that piece, I found some wonky spots that made it look like a patchwork quilt. Not exactly the masterpiece I envisioned. I could almost hear my wife’s voice, “Well, it’s… unique.” I just chuckled because, let’s be honest, I could see the flaws from a mile away.

I took a step back, though, and thought about it. Those imperfect spots were part of the journey, right? I never really was one to aim for perfection, and each little flaw just added character. So, I added some paint, a bit of rustic varnish, and before I knew it, my “Welcome” sign looked like a charming little piece of art. That’s how I learned to appreciate imperfection.

Finding Community

As I got deeper into this woodworking thing, I stumbled upon some local workshops and clubs. You wouldn’t believe the wealth of knowledge I found in those dusty corners with other hobbyists. Sharing stories about our mishaps, like the time Bob carved right through his table or how Sarah accidentally turned a chair into a modern art sculpture—those chats taught me more than any textbook ever could.

The thing is, everyone is just as human as you are. We all whiff it from time to time; there’s always that one project that goes sideways, and it feels so much lighter when you know you’re not alone.

The Warm Takeaway

If there’s one thing I wish someone had told me earlier in this woodworking journey, it’s this: don’t sweat the small stuff. Whether it’s a hiccup with a CNC machine or a project that doesn’t turn out as expected, remember that every misstep is a lesson in disguise. Just get out there and try.

If you’re even slightly thinking about diving into the CNC world or woodworking in general, grab that machine or that piece of wood and go for it. Embrace the journey, make a mess, and just have fun. Who knows, your next hiccup could turn out to be a hidden gem. So, here’s to many more projects, coffee breaks, and, yes, a bit of chaos along the way! Cheers!