Discovering 3D Printing in My Woodshop

So, picture this: I’m sitting in my garage, the smell of sawdust clinging to the air like a warm hug, and I’m sipping some lukewarm coffee out of my favorite old mug—the one with the chipped handle that has survived countless woodworking mishaps. I’ve been a woodworker for quite a while, building everything from chairs to shelves, and, I’ll admit, I usually get a kick out of the simplicity of it all. Wood and a saw, right? But then a few months back, I stumbled onto something that turned my world upside down: 3D printing. Yeah, that thing!

The Unexpected Curiosity

It all started when I was at a local hardware store, picking up some cherry wood for a dining table I’d been dreaming of building for ages. While rummaging through the aisles, I overheard two folks chatting about 3D printing—how it was changing the game for woodworkers. My first thought was skepticism. “What could plastic do for my beloved oak?” But still, I was curious. I mean, we’re in 2023, and at some point, I guess we should all embrace technology, right?

Anyway, after a long week at work, I did a bit of late-night digging online—with a few too many cups of that same lukewarm coffee fueling my quest. I learned about 3D printing, particularly how it could help create jigs and clamps that could save a ton of time and effort in my woodworking projects. I felt like a kid in a candy store. The idea of designing and printing something that fit my needs just perfectly was kind of intoxicating!

First Missteps in the World of 3D Printing

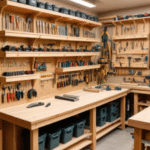

So, I went ahead and ordered a 3D printer. It was a budget model from the local electronics store—nothing fancy, but it looked like it could get the job done. Once it arrived, I set it up hastily in the corner of my workshop, surrounded by bins of tools and wood scraps. I mean, you’d think I’d learned my lesson about reading instructions from building furniture the wrong way too many times, but nope!

I remember the first couple of prints vividly. I thought I’d start simple—a little clamp to hold down some of the scrap wood while I was working on another project. I figured, how hard could it be? Let’s just say it was a total disaster. Watching that printer spit out plastic that looked more like spaghetti than a clamp had me cringing. I almost gave up then, picturing myself throwing the whole thing in the dumpster and sticking to my trusty wood and nails.

But, I’ve learned a lot about perseverance over the years in woodworking. I mean, every piece of wood has its quirks, and so does every tool. So I decided to take a deep breath (and maybe toss back another cup of that awful coffee) and dive back in.

A Lightbulb Moment

After some online tinkering—watching YouTube tutorials and reading up on community forums—I figured out the settings I had totally botched. It was like the stars aligned when I hit that ‘Print’ button again. This time, as the printer whirred away, I could already hear myself laughing with relief. The clamp, this time, looked good! I could actually see it functioning in the shop.

Once I had that basic clamp in my hands, I felt a rush. I was getting somewhere! It was like building a piece of furniture from scratch, but without the worry about the grain of the wood or the right finish. I started daydreaming about all the jigs and aligners I could create.

Bringing it All Together

By now, my small little garage workshop smelled like a mix of freshly cut wood and melted plastic, a strangely comforting combination. I started getting bold—I made a custom circle jig for a project to create some round tabletops. Honestly, I marveled at how that little plastic circle helped me achieve something I’d always dreaded, all while saving me hours of measuring and re-measuring (because we all know measuring once doesn’t always cut it).

Of course, not every print went swimmingly. There were times I’d launch into a new design only to realize just how complicated it was, and I’d get stuck, staring at the printer as if it owed me an explanation. Just last week, I attempted to design a more complex piece—a decorative corner bracket—and, let me tell you, that thing turned out like a twisted pretzel. But I’m learning that’s just part of the deal.

Finding Joy in the Process

Now, it’s not all sunshine and roses. I often find myself wrestling with the tension of being a traditional woodworker while trying to embrace this new tech. I’ve had moments where I regretted mixing both worlds. I considered giving up the whole 3D printing thing when I saw my neighbors down the street still chiseling away at their projects without any of this “modern nonsense.”

But then I remind myself… it’s like when I first picked up a saw. At some point, every great woodworker uses the tools that suit their creative flow—whether it’s an old hand plane or a sleek new 3D printer. The truth is, these days, I can’t imagine my shop without it.

A Warm Takeaway

So, if you’re mulling over stepping into the world of 3D printing, don’t be afraid. Just dive in. If I could figure it out, I believe anyone can. Maybe you’ll make a few twisted pretzels along the way (I know I do), but at the end of the day, it’s about patience, learning, and expanding your toolbox, however you see fit. And hey, if you’re like me, those small victories—like successfully printing that first jig—can feel like the biggest wins in the workshop.

So grab that cup of coffee, roll up your sleeves, and go for it. You might just surprise yourself.